DESIGNERS, SPECIFIERS, BUILDERS, AND DEVELOPERS HAVE EVER-CHANGING NEEDS. Plasti-Fab EPS insulation meets those needs better than other solutions for a number of reasons. For 50 years Plasti-Fab has been the supplier of choice for expanded polystyrene (EPS) insulation product solutions. In those years, we have learned a thing or two about what works for various types of building product applications from residential and commercial construction to geotechnical applications, and so much more.

When your motto is quite literally Quality, Service, Expertise, it is more than just marketing, it is the foundation on which we stand to supply our customers with the best products and solutions. With third-party testing, technical information, and in-house expertise at multiple levels, we can provide recommendations for EPS product solutions for a multitude of applications and stand firmly behind the quality we have established.

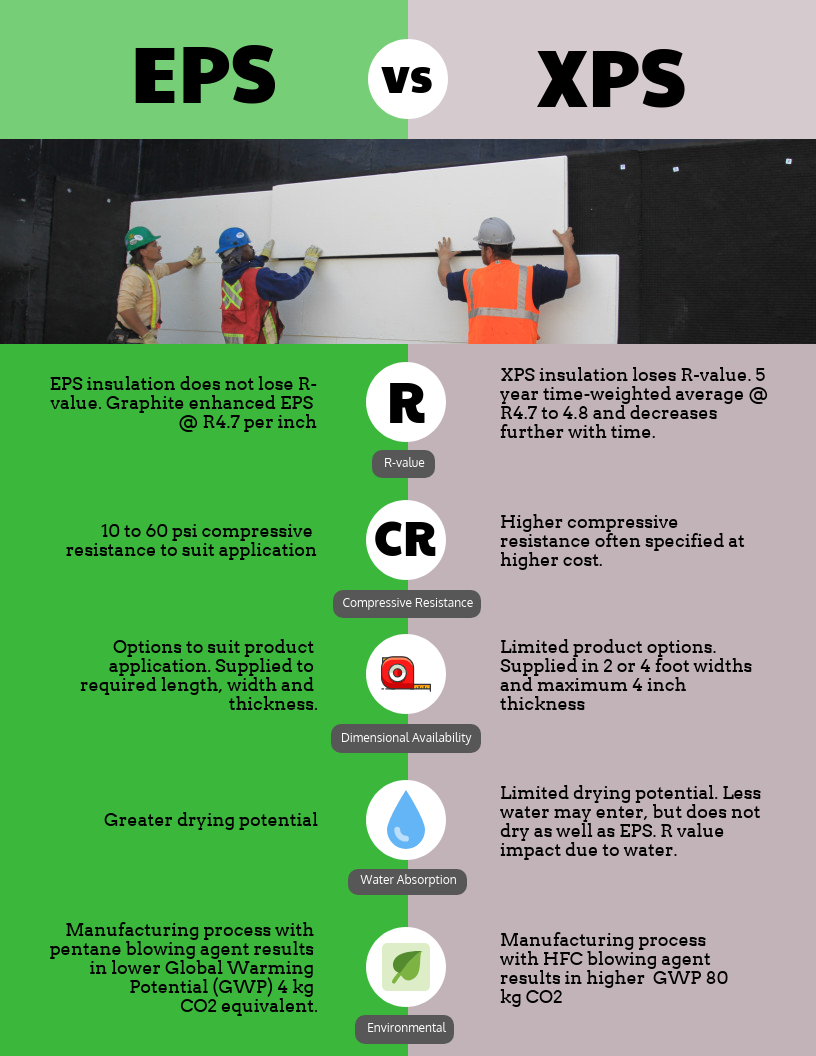

So what exactly are the differences between XPS and EPS foam? We have developed a short infographic to help compare the two:

What is LTTR and why does it matter?

You hear a lot about something called LTTR when comparing various types of rigid foam insulation. The question we frequently get is, what is LTTR and why do I need to care about it?

LTTR stands for Long-Term Thermal Resistance and is a predicted R-value for some cellular plastic insulations manufactured with the intent to retain a blowing agent, other than air, for a period longer than 180 days and is intended to represent their R-value after five years of in situ aging. Certain types of insulation continue to lose R-value over the life of the product, making it necessary for the manufacturers of these products to provide information to you on what they anticipate your R-value to be in the future.

So why does EPS insulation NOT have LTTR listed in the comparison tables between EPS and XPS? LTTR is not applicable to EPS because… It is not manufactured with the intent to retain a blowing agent and due to its closed-cell nature, there is no reduction or loss in R-value over time. EPS has the SAME R-value in the future, as it does on the first day you install it. You can be confident that the R-value you specified and installed, is the same R-value that will perform in that application for the life of the product. See PIB 241 for additional information.